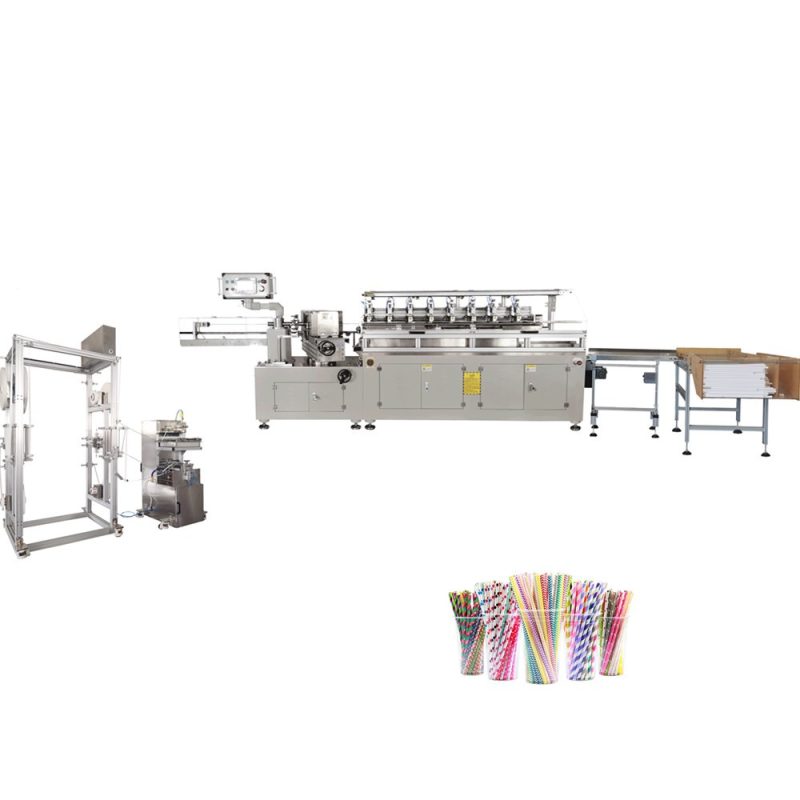

High speed fully automatic degradable producing paper straws Equipment paper drinking straw making machine

描述

High speed paper straw machine with 8 cutters

Machine with following devices:

1. New type of auto splicer (connect paper automatically, for three or four layer, controlled by PLC, more stable)

2. cutting system with protection cover, more safe

3. Machine with 5 sets of servo motor, speed: 70m/min (2kw*1 set,1kw* 2 sets,0.4kw *2 sets) Specification and Parameter:

Specification and Parameter:

Adopted man-machine control interface, touch screen parameters setting, easy for operating.

Controlled by encoder, driven by servomotor. Automatic and high efficiency. Select and use famous brand suppliers for motor and electrical equipment.

Thermal/heat treatment frame to remove internal stress to keep longer service life.

Multi-control language for choosing: English, Chinese, Vietnam, Spain……

Advantage:

1. Higher Speed,max 70-75m/min

2. 8 cutting-knife system, new structure of cutting cylinder. Easier to adjust air cylinder up and down when making different diameter paper

3. 5 sets servo motor for spiraling roller, cutting system moving left & right, supporting roller and cutting

4. Auto paper roll connecting function hanging bracket, auto splicer, 4 layers. Other brand paper straw making machine paper roll hanging bracket is only 3 layers.

5. Auto feeding function glue

6. Auto lubrication grease feeding system for cutting

7. Main electric parts choose famous brand, Schneider. Like main servo motor, servo motor driver, frequency converter, touch screen

| Number of paper layer |

3-4 layer |

| Max. outer diameter | 12mm |

| Min. outer diameter | 5mm |

| Max. thickness | 1mm |

| Min. thickness | 0.5mm |

| Min. length | 110mm |

| Making speed | 10-80m/min |

| Winding part | 2pcs winding roller/1pc belt |

| Number of knives | 8 cutting knives |

| Glue adding method | Double/Single side |

| Length fixing method | encoder |

| Operator | 1 worker |

| Shaft fixing method | Chuck |

| Speed control | Servo |

| Power supply | 3P/380V/50HZ |

| Main part size | 4050×1200×1600mm |

| Machine take space | 8500×3500×1900mm |

| Wheel diameter | 210mm |

| Wheel Height | 120mm |

| Total weight | 1350KGS |

| Servo driving | Schneider |

| Touch screen | Schneider |

| Program version | GD-XJ2.0 |

| Servo motor | Schneider |

| Actuator | Schneider |

| Max. length(distance between 2 knives) |

1450mm |

| Signal element | Omron |

| Pneumatic Components |

AirTAC |

| Synchronous control | Synchronous belt |

| Synchronous tracking and cutting system | Synchronization tracking system |

| Pipe rack | Have |

| Belt angle adjustment | Runner adjustment |

| Belt tension control | Runner adjustment |

| Auto glue device | With pump |

| lubricating | Automatically add grease |

| Paper tension control | Continuous tension control |

| Paper roll reel | Auto paper splicer for 3/4 layer |

1. New improved type auto splicer (automatic paper connection device)

Use:

It is used for connection paper automatically, which can be used for 3 or 4 layer. Advantage is take less space and save labor. It is controlled by two PLC. It is more stable and faster

Specifications:

Size:1250mmx1000mmx2050mm

Paper:can be used for 3 or 4 layer paper

Speed:90-120meter/min

Weight:240kg

The air supply can connect with paper straw machine

Power supply:available for 110V-240V,50HZ-55HZ,single phase

With convenient operation and stable performance.

This dryer is used to connect with machine, which to dry products quickly, sterilize it, and improve product safety and quality.

Control mode: PLC and HMI (touch screen) control, high degree of automation

Use environment:

1 Input power: three-phase 380V±10% (three-phase five-wire system) 50Hz±1%

2 Distribution power: ≤9KVA

3 Ambient temperature: -5~40℃, relative humidity ≤80%, no flammable and explosive gas or dust

Microwave system

1 Microwave frequency: 2450±50MHz

2 Microwave output power: 6KW (effective heating length 1.42 meters)

3 Microwave box body is made of 304 stainless steel plate

4 Microwave conveyor belt: special microwave chain plate (width 460), the angle of the guide plate at the discharge end can be adjusted, and the adjustment foot selects the enhanced type (80).

5 Speed adjustment: 0.4-4m/min continuously adjustable, using frequency conversion control technology to ensure stable and reliable speed

6 Cooling method: Magnetron air cooling.

7 Microwave leakage energy: meet the national GB10436-2008 microwave radiation safety standard (≤5mw/cm2)

8 Infrared temperature measurement, temperature measurement range, accuracy: 0-500℃, accuracy ±1℃

9 Microwave power adjustment range: 0-6KW continuously adjustable

10 Control mode: PLC and HMI (touch screen) control, high degree of automation

11 Microwave drying equipment size: 3900×640×1800mm (L*W*H)

12 Net weight of equipment: 550kgs